The part of the foundation, which rises to the level of the soil, is to be lined with brick material. Features of the dimensions allow you to display masonry rows up to 2 meters high. Outwardly, such a design looks overall and majestic, visually separating the foundation zone from the supporting elements of the structure. To know which brick is best for the basement of the foundation, you will have to deal with the classification of this building material.

Criteria for choosing brick material during the construction of the basement

Why do you need a plinth at all? It is believed that it holds the maximum load impacts from any structure. At the same time, its operation takes place in close proximity to the ground, under the negative effect of precipitation and water in the ground. The upper sections of the walls get wet slightly, but the basement part accounts for the largest amount of moisture from the entire surface rising above it.

To protect the plinth from the negative manifestations of the climate, a fine finish is used for wall surfaces.

The characteristics for the basement are approved by SNiP II 22 81, which states that stones, cellular concrete blocks, ceramic bricks or other material made using the dry technology method are not allowed to be used for decoration.

The main requirement related to brick is the value of compressive and bending strength.

Consider the case of erecting a brick base on strip foundation under the outbuilding. The building material must meet the following characteristics:

- frost resistance. This indicator depends on the brand of brick stone and its production technology, and ranges from twenty-five to one hundred cycles;

- water permeability - the value varies from two to twelve percent;

- strength should be at least m125. At the same time, builders recommend choosing such an indicator with a margin. And if you are in doubt which brick is better than m100 or m125, feel free to choose the second option.

Types of brick material

For the construction of the basement, it is best to use one of the materials below.

It is made from a special type of clay, fired in kilns at a high temperature. This type of building material is considered expensive, looks attractive and has good strength - from three hundred kilograms per square centimeter. Moisture absorption of bricks is not less than six percent, frost resistance is not less than one hundred cycles.

In addition, the clinker material is known for its good noise insulation properties, it creates excellent security for the upper part of the foundation. If you correctly lay out the base of this brick on the foundation, its operational period reaches one hundred years.

Acid-resistant brick

This stone material is considered "eternal". For its manufacture, clay is used with an excellent level of plasticity and a value of resistance to ignition. In itself, it contains silica, metal oxides and alumina. After the firing procedure, the material becomes yellow.

The brick is produced in several versions - straight, end double-sided and ribbed. It has a low level of moisture absorption, almost does not get wet, which is why it is considered a good option for arranging the basement.

Ceramic red brick

The material is universal, known in the construction industry for a long time. It is made under the influence of high temperature, followed by drying in special chambers.

Red brick has gained popularity because of its strength and long service life.

The main advantage of this material is its affordable cost. For the manufacture of bricks, quartz sand and lime are used, so such material is of little use for operation in a humid environment. And if you are going to lay a plinth of such a brick on the foundation for a bath, give up your idea and use a different material.

The use of silicate brick is allowed in regions with a dry climate.

Consider how to lay a brick base on a strip foundation with your own hands.

The algorithm of actions is as follows:

- first of all, you will have to calculate how many bricks are needed for the foundation base. To do this, you should know the parameters of the walls planned for construction, and the dimensions of the brick stone. If work is to be done with material of non-standard parameters, then the volume of the basement is calculated, which is divided by the volume of one brick. Calculations are simple, do not cause difficulties;

- before you start laying a brick base, you need to check the horizontal foundation of the foundation. If the work was done with high quality, then the maximum deviations will not exceed a couple of centimeters, which is easily eliminated by removing the first basement row. If large deviations are found during the check, the tape will have to be aligned. So, how to lay a brick base with your own hands on an uneven foundation? To begin with, slats are vertically attached to the corner sections. On one, the horizontal is beaten off, we transfer its value to another bar. We stretch the rope according to the marks, measure the distances to the foundation surface. This will help calculate the approximate working volumes and the need for materials. To eliminate irregularities of more than two centimeters, it will be necessary to prepare a concrete solution, smaller errors are eliminated with a mixture of sand and cement. It is allowed to work "by eye", since the brick line following the mortar layer will be displayed in level. The leveling layer must dry well, which will take at least two weeks. Only after that is it allowed to lay the basement brick on the foundation;

- before starting masonry work, roofing material is laid on the foundation tape in two layers. The device of this waterproofing layer is an important condition, because the plinth can quickly collapse from exposure to moisture;

- laying begins with two corner sections. If you are new to this business, just practice laying out bricks without masonry mortar until the movements become automatic. Do not forget to use the tools for quality control of work. Required condition- dressings, alternation of spoon and tychkovy rows. To make it easier to control your work, bring the height of the corners to a maximum of five to seven stones;

- a nail is driven in along the initial row, a cord is pulled. You need to make sure that the twine runs along the brick edges. The preparation is over, you can proceed to the device of the basement rows.

Typical errors

Why do we need a brick base on a strip foundation, we know. Remember that this is an important element of the building, which will be impossible to repair. And if the brick base on the strip foundation begins to collapse, you will not correct the situation.

Beginning masters often face certain problems that need to be addressed correctly. For example, is it allowed to apply a mortar whose thickness exceeds one centimeter to level the surface? As a rule, such a need arises when constructing a brick base on pile foundation. It is better to entrust such work to experienced craftsmen, since you will have to constantly monitor the vertical.

Is it allowed to use bricks made without firing? It is undesirable, but if there is no other way out, then they arrange a base from such material. True, unbaked brick should be laid inside the basement masonry.

Varieties of plinths

This is determined by the location of the front wall of the basement in relation to the front:

- speaker. The option is used when it is necessary to increase the bearing capacity of the base. In this case, the element is extended two to three centimeters beyond the wall plane. There is a drawback - you will have to take measures to remove rainwater flowing down the building;

- sinking. The façade wall hangs over the basement. It is best to use this option when durable building materials were used to make the basement, which do not need additional finishing;

- in one plane. The basement and the wall are in the same plane. This method is rarely used and mainly on outbuildings of secondary importance. The finishing layer is made with one material.

There are no specific requirements for the height of the basement - everything is determined by the presence of the basement and the foundation itself.

Since the basement structure is in direct contact with the soil composition, the brick must meet certain requirements for aesthetic appearance and strength.

In addition, the material must perfectly withstand the effects of a humid environment, have a sufficient level of frost resistance, and be environmentally friendly. In addition, it must be of reasonable cost.

Before choosing a brick for the basement, you should study some general requirements. First of all, the stone must be of the same parameters and shapes. Surface building material should be even, not have chipped areas and cracks, have the same color scheme.

It is mandatory to check the brand of brick material according to the quality certificate, the date of its manufacture, technical characteristics. If the basement material is chosen correctly, more heat will be stored in the premises, the building will receive better protection from the penetration of cold air masses from the street.

When choosing a brick stone for arranging the basement, the aesthetic component is also taken into account - the masonry should be perfectly combined with the erected walls. For example, ceramic bricks look great with walls made of smooth materials. If you have sufficient skills, curly masonry can be used to equip the basement rows. In this case, the brick serves as an unusual decoration.

Conclusion

Before starting the construction of the basement, it is recommended to carefully perform the necessary measurements, because the choice of building material is most often determined by the expected load effects. Brick in this type of work is the optimal and cost-effective material.

The choice of brick for the foundation

Brick is ceramic and silicate.

Silicate will be rejected immediately: it is not suitable for the foundation. Why? It has a large (compared to ceramic) water absorption, and such a foundation will not be strong.

Now you need to figure out how to choose whether the ceramic (red) brick you have looked at is suitable for use in building the foundation of your house.

Of course, to build a foundation, you need to use a solid brick (it is also called building, ordinary or ordinary): it has high flexural and compressive strength, responds normally to temperature changes, is moisture resistant, and has high adhesion strength to the mortar when laying (although its the heat-shielding ability is quite low, therefore it is better not to use it for the construction of walls - or immediately rely on additional wall insulation).

The right brick should ring on impact (and, of course, not crumble): this means that all technical requirements were met during its production.

Check the surface of the brick: if it is not even, and melting is visible on it, the production requirements have been violated.

Frost resistance of bricks must have at least 25 cycles. This figure indicates how many freeze-thaw "cycles" a brick must withstand without showing signs of destruction.

For construction in the "latitude" of the Moscow region, it is better to use brick with a frost resistance of 35 cycles or higher.

Also an important characteristic is the brand of brick, it shows what kind of load such a brick can withstand (for example, M 100 must withstand a load of 100 kilograms per square centimeter). In principle, it is this brand that you need: after all, the M 150 is usually used in the construction of multi-storey buildings.

Another characteristic of a brick is water absorption. Water absorption in the range of 6 to 12% is considered acceptable. The lower - the better (since the higher the water absorption - the lower the frost resistance). If you put your finger moistened with water on a brick and the water is immediately absorbed, then the water absorption is high, the frost resistance is low, and such a brick is not suitable for you.

Also a good material for the foundation is clinker brick, which is one of the varieties of ceramic: it is distinguished by special strength, durability, resistance to external damage, and frost resistance.

Articles by sections:

Foundation brick

Many who want to build a country house at no extra cost on their own are wondering: what material is best suited for the foundation? One of the most used elements of building materials is a brick for the foundation. This is an artificial stone, which has a rectangular shape convenient for buildings and has a number of positive properties: strength, durability, breathability.

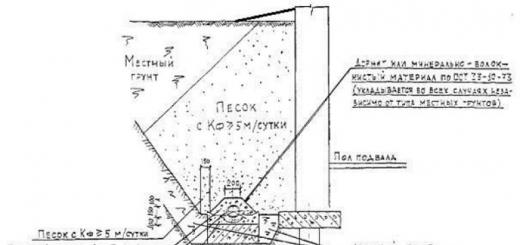

Brick is most often used under the base for temporary, light, suburban structures. Such a foundation can be tape or columnar. It is important to consider that it is built either on dry, immovable ground, or requires careful waterproofing, since the brick is porous in structure and absorbs moisture. In climatic conditions with seasonal temperature changes, this is fraught with its destruction.

The next important question is: what brand of brick to choose for the foundation? There are two types of this artificial stone: white (silicate) and red (clay). They differ in strength (due to different density) and size. Red brick has better characteristics than silicate brick, since fired clay stone does not break down as quickly under the influence of moisture. It is also divided into several types: ordinary, facial, special.

Which brick is better for the foundation

Each one is for different construction works.

- Ordinary red brick is corpulent and hollow. The first option can be used both for the base and for the basement floors. The second #8212 is more suitable for building walls and partitions.

- Front - decorative (color, textured) and light, retains heat. It is used only for cladding.

- Special refractory (with the addition of fireclay) - designed for stoves, fireplaces, chimneys.

The red brick foundation is convenient in construction due to its optimal size and light weight. It fits well, adjusts and adheres with cement mortar, is not susceptible to mold and is environmentally friendly. For its laying, heavy specialized equipment is not required, as, for example, when installing monolithic blocks.

Even one person or a small team can build a brick foundation. The design is ideal for low-rise construction. The base does not interfere with the construction of the basement (if groundwater permits).

If the technology is observed and the load of the load-bearing walls is correctly calculated, the foundation will last up to 50 years. In the future, it can be partially repaired without exposing the structure to the risk of destruction.

Flaws

- brick foundation 30 cm wide is designed for light weight - no more than 14 t / m2.

- Due to its porosity, it is able to absorb moisture. It, in turn, freezes at low temperatures, and then thaws when warming and gradually destroys the structure. Therefore, waterproofing, drainage and protection from groundwater are required.

- It is not recommended to put the foundation in a swampy area. You should not build it where floods are possible or underground sources are shallow.

- Planting trees close to the building should be avoided. If they are already growing there, it is better to uproot them. The root system, growing, will damage the base, leading to cracks in the walls.

- It is impossible to call such a building quickly erected. Installation takes much longer than other types. But the shrinkage period is much less.

Choice and purchase

Too cheap brick is defective or used. To choose a quality one, you need to pay attention to its color, shape, strength, ability to repel moisture.

Too bright or vice versa, a faded uneven shade indicates a violation of production technology. A loose, uneven brick that crumbles is not suitable for a solid foundation. This is a sign that it has been used somewhere before, and therefore will not last long.

Also, the foundation brick should not instantly absorb water, otherwise it will quickly collapse. These simple recommendations will help you choose a quality material or, conversely, bring down the price by pointing out the shortcomings of the raw materials.

In Moscow, you can buy a brick for the base at a price of 13 to 17 rubles / piece. It will be of high quality, strength M125, M200, with corrugated sides for better bonding with cement. The cheapest red will cost about 8 rubles / piece.

Strip foundation

First you need to find out the properties of the soil (its level of freezing, humidity) to make sure that it is suitable for brick construction. For surface water (precipitation), it is better to drain immediately.

It is not difficult to build a foundation with your own hands from brick, even without special knowledge and proper preparation. To do this, you will need: brick, cement, crushed stone, sand, waterproofing. And you will need tools and equipment: a building level, a tape measure, a shovel, a trowel, pegs, a cord, a container for cement mortar.

- The first thing to do is clear the site of debris and plants. The fertile layer of soil is usually removed and transferred to another place, where it will still serve for other purposes.

- Then you need to mark the territory, drive in pegs around the perimeter and pull the rope so that you can see where to dig a trench (or pit).

- Now you need to dig a hole of sufficient depth.

- A pillow of sand with crushed stone about 10 cm thick is laid at the bottom of the trench.

- After that, waterproofing is laid.

- In order to make the foundation more reliable, a concrete sole is poured under it, which should harden well. This is where the preparation ends.

- Next, laying begins. All gaps between bricks are filled with mortar. The width of the seams should not exceed 10 mm. If necessary, it can be reinforced with a reinforced mesh.

- At the final stage, when the cement dries, it is necessary to cover the external and internal walls with waterproofing. Finally, you can fill the ground along the masonry.

Column Foundation

This foundation is no less in demand than the previous one. Its distinguishing feature is economy. This is justified for the construction of light buildings: baths, kitchens, wooden houses without a basement, gazebos, utility rooms. It is also appropriate in cases where the height difference of the soil surface is about 2 m. Another plus is less land work.

For such a foundation, red solid brick M-150 and above is used, as it is durable and resistant to moisture. According to the types of laying, it is divided into shallow-depth (up to 70 cm) and deep-seated (up to 2 m). The pillars are placed at a distance of 1.5-2 m. The protrusion above the ground is left at least 30-50 cm (lower is unjustified - it is difficult to repair plumbing). The cross section and number of columns is calculated taking into account the weight of the building.

The steps here are:

- site leveling

- markup

- well digging

- pillow laying

- waterproofing

- concrete screed with reinforcement

- building supports

- treatment of pillars with waterproofing.

After that, the space in the trenches is filled with crushed stone, sand or gravel. To improve the appearance of the building, after completion of the work, the pillars are covered with bricks, decorative stone, wood or living shrubs. Subject to the technological process using high-quality materials, the foundation will last for decades.

What brick to use for the plinth

A plinth is a foundation located above the ground surface. It is best to make it out of brick. The plinth is located in close proximity to the ground, so it gets wet very quickly from melt water and rain.

A brick plinth encloses the underground space of the building from the outside; in most cases, it is a continuation of the foundation, extending from ground level to the floor of the lower floor.

Only certain types of bricks can withstand constant wetting and drying.

Another danger for the #8211 plinth is getting wet from the moisture contained in the ground. Moisture rises from the soil through the capillaries of the material through the foundation and penetrates into brickwork plinth. In winter, in the cold, water freezes, and, increasing in volume, the capillaries break. After repeating this process from year to year, the destruction of the masonry begins.

Through the capillaries of the material, water rises from the ground through the foundation and enters the brickwork of the basement. In frosts in winter, water freezes and breaks the capillaries, increasing in volume. To stop such destruction, it is necessary to waterproof the basement.

When choosing which material is better to choose for the construction of the basement, it is necessary to take into account its combination with other materials used for the walls of the building. For example, a plinth made of stone or brick will look very good with smooth wall surfaces. When building ordinary brick walls burnt clay ordinary brick will look good. Silicate and lightweight bricks are used only when constructing a basement located above the waterproofing layer. At the same time, it is imperative to line its outer surface with ordinary clay bricks or other weather-resistant materials (for example, cover with reinforced concrete slabs).

The reasons why the question of what material to choose for the plinth is very important:

- the basement is in an unfavorable environment compared to the walls of the house

- when it rains, drops constantly fall on the blind area and wet the basement of the house (this makes it constantly wet)

- when it snows, snowdrifts are often near the plinth, and during the melting, the plinth gets wet

- there will be a huge load on it from above (both plates and walls, roofs, etc.)

- it is loaded from below (due to tangential frost heaving of the soil)

- when the plinth gets wet, frost expands the moisture and the plinth is destroyed.

Therefore, it is very important to choose the most durable material for the plinth.

The brick for the base must meet the main indicators: strength, the ability to absorb moisture and frost resistance.

The durability of the building material is based on the main indicators:

- Strength #8211 is determined by the compressive strength limits that the material can withstand before the failure phase begins. The bigger it is, the better, of course.

- Moisture Absorbency #8211 is defined as the ability of a material to absorb moisture until fully saturated. The lower the absorption rate, the better. A high rate of moisture absorption does not provide high frost resistance.

- Frost resistance #8211 is determined by calculating the number of freeze-thaw cycles that it can withstand before it starts to break down.

These three parameters are closely related.

Tool needed to determine the suitability of bricks for plinth construction, #8211 cold stores, moisture meters, scales, presses and others to test the basic characteristics of the material. Research is carried out in the factory. The manufacturer fixes the results in quality certificates.

Consider the main types of bricks that can be used for these purposes.

Clinker brick

Clinker brick is one of the elite materials, characterized by high characteristics of strength and attractiveness.

In comparison with front ceramic and facade plaster, clinker has a lot of advantages. The main ones #8211 are reliability and durability. The ability to absorb moisture is 3-5% of the volumetric mass of the material.

The defining property of clinker as a building material is its high reliability. Not a single facade brick can compare with it in terms of its ability to protect the facade from the adverse effects of the environment.

Facade made of clinker bricks. does not change its original color and does not require any operational maintenance. Manufacturers producing this brand often give a guarantee on the material for more than 100 years from the date the building was put into operation.

As a material for the construction of the base, it can be recommended in the first place.

Acid-resistant analogue

Acid-resistant brick is resistant to aggressive environments and to physical influences and high temperatures. In addition, this type of brick is characterized by low water absorption.

This building material is not in vain considered eternal. It is able to withstand any natural and various aggressive influences. Acid-resistant brick has a very high strength. The level of moisture absorption is quite low.

It is produced from special raw materials. Its most basic components are special clay and dunite. Very careful processing of the material gives it resistance to aggressive environments and physical influences. It can be quite resistant to high temperatures.

Such material is produced only according to the state standard. Therefore, during the purchase, be sure to pay attention to this. Poorly made brick leads to a violation of both the health of people and damage to equipment. Harmful substances will be released into the environment.

The material is used where serious protection is needed. Acid-resistant brick can easily withstand both a small load of a small building and a high load of a multi-storey building.

silicate material

Silicate brick has high thermal conductivity and moisture absorption, has a high rate of sound insulation. Due to its high density, it can be used in buildings with a large load on load-bearing walls.

This type of building material is most often needed for the construction of walls. When building a plinth from silicate material, it is imperative to finish the outer surface. It has a relatively low cost and good construction qualities: the correct shape, accurate dimensions and the necessary strength. It is made from quartz sand and lime.

According to established standards, the ability of this building material to absorb moisture is from 8 to 16%.

When constructing the basement of a building, it can only be used if the climate is sufficiently dry. Under normal conditions with average rainfall, its use is not recommended.

Ceramic solid red brick

ceramic brick resistant to moisture, temperature extremes and frost.

A versatile material that is suitable for all kinds of construction work: the construction of foundations, partitions, walls. It can be used to make fireplaces and stoves. It is also applicable for laying the basement of the building.

Whatever material you choose, always consider how long you want your building to last. In construction, it is always better to do everything once with high quality and for a long time. Saving on this material is equivalent to building a castle in the sand. When destructive processes begin, you will need to rebuild the entire structure.

Official standards for a brick base existed exclusively in Tsarist Russia. At present, the construction of this structural element of the building is justified in the presence of an underground level (basement, technical underground or a whole floor), the need to level the foundation, use it as a decorative element of the facades, if the foundation is poured flush with the ground.

According to the terminology of the SNiP regulations of 1980, number I-2, the basement is the lower part of the wall, which can sink / protrude relative to its plane (usually ¼ of a brick) or be flush with it. To understand why a brick base is needed, it is necessary to take into account the options used to build the building technologies:

- on a slab base, a plinth is necessary for the manufacture of a technical underground;

- if a strip foundation is used (prefabricated from reinforced concrete blocks or monolithic), the horizontal level is leveled with masonry for laying floors;

- when choosing the technology of a log house, a “framework”, a cottage made of SIP panels, a brick plinth is necessary for an even distribution of structural, operational loads on the base of the house;

- the foundation is poured at the zero mark (ground level), the basement provides the necessary level of the floor of the first floor.

Depending on the type of construction, the base has both advantages and disadvantages:

- protruding - decorates the facade, emphasizes the original architecture, but quickly collapses without cladding;

- construction, when facing, the thickness is aligned with the walls;

- flush - in fact, it is a continuation of the walls, when finishing it becomes protruding.

The choice of the design of this element is made during the design, depending on the preferences of the owner.

Technology for the manufacture of brick plinth

Having decided what a brick base is for, you can start building. For laying the foot of the building does not require high qualifications, special equipment.

Material selection

Experts do not recommend the use of silicate bricks, concrete blocks due to the maximum hygroscopicity of these materials. In addition to destruction from the moisture they absorb from the air, the earth, they transfer it to the walls or to the foundation. In addition, decorative plaster, which is most often finished with masonry, does not adhere well to their surface. the best choice are:

- clinker is the most durable of existing analogues, has a high resource, does not require finishing, is absolutely waterproof, but too expensive, therefore it is rarely used;

- clay - more often called ordinary, has a minimal aesthetics of perception, decoration is necessary, the material is chosen for frost resistance (M 150 - M 250 for 50 - 100 seasons, respectively), this is a budget brick that allows you to reduce the construction budget;

- ceramics - average price, excellent decorative properties, there are full-bodied, hollow modifications;

- porous - minimally loads the foundation structure, does not need cladding, is an improved analogue of ceramics, therefore it costs more, there are large-format modifications with non-standard sizes;

- dry, semi-dry pressing - outwardly resembles ceramics, but is not fired, has less frost resistance, is inexpensive, masonry does not need lining;

Solid clay brick is the most suitable material for a plinth.

When choosing a brick other than the walls, the plinth by default becomes an independent design element of the facades.

What tools will be required

To build a brick base, you will need a standard trowel, level, mooring, plumb line, cord, pick. When using facing bricks, it is better to cut with an angle grinder (grinder) with a diamond blade or stone tooling. For the solution, you will need a bucket with a shovel or a bucket with a drill, a mixer. Professionals are able to get by with a piece of roofing material or a sheet of iron, it is better for a home master not to risk the quality of the batches.

For facing masonry special devices are produced to facilitate the leveling of pastels in each row. The only drawback of the Bricky fixture is its adaptation to foreign bricks, the dimensions of which are somewhat different from domestic counterparts.

Choice of plinth width

The brick plinth has a width depending on the selected type (flush, protruding, protruding), wall thickness. For example, for masonry 51 cm, this value is in the range of 45-57 cm. There are options when the foot is wider than the foundation - in this case, the release of a brick on any side is limited to ¼ of its length (6 cm). If for the thickness of the walls a similar overlap of masonry of the first row along the base is not enough, the foundation will have to be added from the convenient side, increasing its width.

What height to make the base

Due to the lack of regulatory documentation for the construction of the foot of the house, the brick base can be of arbitrary height. Experts do not recommend building it above half of the first floor - this will violate the architecture of the building, the exterior of the facades.

Without a project, only garden houses can be built; in all other cases, the necessary marks for all structures are included in the documentation. Self-builders solve the problem of the height of the foot as follows:

- if the foundation is poured at ground level, choose a masonry height of 0.7-1 m;

- if a basement is needed for a technical underground, they are guided by the dimensions of the engineering systems (usually pumping equipment, valves) that should fit in it;

- if the foot is necessary to complete the basement floor, choose a comfortable ceiling height in the lower level.

In the last two options, insulation is often placed in the basement design (if the brick is facing) or external insulation is performed, taking into account its thickness.

Foundation waterproofing

Unlike the outdoor soil, the ground under the house does not freeze in any frost. It contains moisture absorbed by concrete, transmitted to the upper structures. Therefore, the foundation is necessarily cut off from them with a waterproofing layer.

In order to waterproof the foundation with high quality, it is enough to lay two layers of roll material, a membrane or a film around its perimeter. The side surfaces of the concrete tape also need to be treated to protect against flood, ground, melt water. In this case, deep penetration primers that change the structure of the material are much more effective.

The upper waterproofing is overlapped at the joints, protrudes 2-3 cm beyond the perimeter, cut off at the end of the masonry.

markup

Before laying on the waterproofing layer, it does not hurt to check the diagonals, the compliance of the foundation dimensions with the design dimensions. To do this, the easiest way is to install pegs in the corners (0.5-0.7 m from the base of the dwelling), stretch the cords. This will allow you to measure the length of the walls, diagonals with an accuracy of 1 cm.

Ventilation products

The tape base will not be effective if ventilation holes are not left in it. When using bricks, they do not have to be made round; you can make small rectangular, square windows using sheet steel and reinforcement as lintels.

They should be on all walls, including internal partitions. It is impossible to close them for the winter with insulation, plugs - humidity is present in this space all year round. Therefore, it is more reasonable to lay decorative lattices in the masonry or provide for their sizes during construction.

Proportions for mortar

When laying bricks on a strip foundation, a plastic mortar is required. In the standard version, for the manufacture of different grades, different proportions of sand and cement are used, respectively:

- M75 - 3/1

- M50 - 4/1

- M25 - 5/1

The base will be stronger if you use the first two options. At the same time, it is necessary to check the quality of sand using available methods:

- Squeeze a handful of non-metallic material in your hand with some effort;

- Loosen your grip to check the result;

- If the sand woke up on the ground completely, partially, there is a minimum amount of clay impurities in it, in the case of a lump formed (more than 2/3), there is too much clay in the sand for a normal solution.

Excess clay is dangerous due to the forces of frost heaving arising in it - in winter, the masonry may crack. The plasticity of the solution can be given with ordinary soap or detergents by adding a couple of Fairy caps when kneading.

Making corners

To increase the pace stone work the corners are usually laid out on a strip foundation along a plumb line / level, after which the cords are pulled, the walls are periodically controlled by the rule. Laying corners traditionally requires a highly skilled craftsman or the use of orders. The main condition for the maximum resource of the base is the dressing of vertical, horizontal seams. Depending on the height of the base, an in-line or multi-row dressing can be used:

For laying one and a half bricks, it looks like

Scheme of a single-row dressing of the corners of a brick base of a strip foundation, a wall of 1.5 bricks.

For multi-row dressing, a different scheme is used

Scheme of multi-row dressing of the corners of a brick base of a strip foundation, a wall of 1.5 bricks

When choosing a base in two bricks, the design of the ligation of the corners changes as follows

Scheme of a single-row dressing of the corners of a brick base of a strip foundation, a wall of 2 bricks.

The number of pins here is higher than in the previous case. For multi-row dressing, the scheme is more complicated

Scheme of a multi-row dressing of the corners of a brick base of a strip foundation, a wall of 2 bricks.

Plinth decoration

At the final stage, the strip plinth made of ordinary brick must be lined. For this, facade plasters or special claddings are used:

- basement siding - imitation of stone, brickwork;

- stone - artificial, natural;

- porcelain stoneware is a large-format material with high frost resistance.

Facing is usually done after the construction of the building box, roofing. Using the orders, recommendations of specialists, the home master will be able to avoid mistakes, get the maximum design resource, and ensure a reduction in the construction budget.

Everyone knows how important good foundation for home. However, when doing construction with their own hands, many simply forget about the need to equip the basement. But in vain, because it performs an important role as a support for the walls, and also fences off the residential part of the building from getting cold inside. Therefore, the choice of material for its arrangement must be given special attention.

At the same time, it is far from always that the inhabitants of our country can decide which brick is better for arranging the basement of the foundation. The choice on the market today is simply huge: full-bodied and  hollow, clay, silicate and ceramic ... Due to the complexity of the choice and the considerable cost of building material, some people generally prefer to build a house without a basement, which is not recommended. Today we will talk about which option will be the best.

hollow, clay, silicate and ceramic ... Due to the complexity of the choice and the considerable cost of building material, some people generally prefer to build a house without a basement, which is not recommended. Today we will talk about which option will be the best.

A common question is: why should you stop at a brick? Advantages  of this material are quite simple:

of this material are quite simple:

- Multifunctional.

- Handsome.

- Relatively inexpensive.

In addition, there is no need for additional finishing.

When choosing a building material, you need to pay attention to the following characteristics:

- reliability;

- durability;

- decorative properties.

The building material for the base must be resistant to deformation and look great. In addition, it is necessary to pay attention to the brand of material, moisture-absorbing properties and the ability to tolerate frost. These characteristics are endowed with many building materials, the structure of which is similar to red brick.

Brick types

The modern market offers us a huge selection of building materials. In order to make the right choice, it is necessary to study in detail their main types and properties. The most common today are three types of building materials:

The modern market offers us a huge selection of building materials. In order to make the right choice, it is necessary to study in detail their main types and properties. The most common today are three types of building materials:

- silicate stone;

- clay (red brick);

- ceramic stone.

Each of them has found wide application in the construction of private and multi-storey buildings. Let's consider them in more detail.

silicate brick. This building material is made in such a way that it is absolutely impossible to use it in places with high humidity. The problem is that silicates are able to absorb water, swell and gradually lose strength. High humidity leads to the rapid destruction of the brick, so it can only be used in two cases:

- When constructing a building in a dry climate with little rainfall per year.

- With the arrangement of good, high-quality waterproofing.

In principle, such bricks can be used to create good waterproofing. If you intend to opt for them, be sure to choose brands that are characterized by increased strength.

Clay or red brick. A huge advantage of such a stone is the technology of its production. Unlike silicates, they are created using baking technology rather than pressing. Accordingly, from a technical point of view, clay bricks more suitable for arranging the foundation and basement. But there is also an important drawback: the ability to absorb moisture.

To avoid problems of this kind, you should pay special attention to the brand of brick. To  for example, the M150 would be a good solution. Such a stone has excellent resistance to cold, withstanding up to 60 cycles of freezing and thawing. However, many factories produce products that can withstand even more cycles. For example, if you live in a region with a humid or frosty climate, choosing an M250 brick would be a much better solution.

for example, the M150 would be a good solution. Such a stone has excellent resistance to cold, withstanding up to 60 cycles of freezing and thawing. However, many factories produce products that can withstand even more cycles. For example, if you live in a region with a humid or frosty climate, choosing an M250 brick would be a much better solution.

Why should such attention be paid to the resistance of stone to frost and moisture? First of all, because of the increased strength and long service life of such houses. Moisture can get into small cracks in the stone and freeze there, causing the material to crumble. The higher the resistance of the material to freezing, the longer it will serve you. Even in dry climatic conditions, it is recommended to use clay bricks for construction.

Ceramic brick. This material has the greatest durability among all options. Its advantage is absolute moisture resistance and frost resistance. The bearing properties of this product are approximately similar to clay building materials. It is also produced by baking, thanks to which it was possible to achieve such advantages. Perhaps this option will be the most preferable in order to equip the basement in the house. However, its cost is quite high, and therefore it is worth weighing the pros and cons of such a decision. If you have the opportunity to spend the best option you just won't find it.

What is a plinth - this is the lower part of the wall of the building, which is located directly on the foundation.

Plinth photo

It is the most vulnerable section of the wall, because it is exposed to moisture and frost the most. The main purpose of the basement building is to protect the building from the penetration of moisture from rain or lying snow. (More information about this can be obtained from this article) The foot structure is erected directly on the foundation and reaches the floor level of the first floor in height. Special requirements are imposed on the material from which the basement is built:

- strength to withstand heavy loads;

- weather resistance;

Which brick is better to use for the basement

The laying material should not be inferior in its quality parameters to the properties of the foundation, if raw materials with distinctive characteristics are used, the entire structure may be destroyed. The most optimal raw material for the foot is best to choose:

Not every brick is suitable for the base

- foundation concrete blocks;

- concrete that was used to pour the foundation;

- e or brick products.

The most widespread in the arrangement of the basement received. For such work, two types of facing brick block can be used:

- clinker;

Clinker brick for plinth

In the production of this type of ceramic products, special raw materials are used - clay, which is characterized by increased refractoriness. Clay is sintered at very high temperatures. The temperature value for firing clinkers is much higher than the limit value of the production process of conventional blocks. Thanks to a special technology, the texture is homogeneous without air voids and pores. The finished product has the following properties:

Clinker brick plinth photo

- Strength. Clinker can be called the most durable of all types of brick products, because it is resistant to any impacts and mechanical stress. This building material retains its strength for decades.

- Weather resistance. Clinker is not afraid of any kind of precipitation and wind, as well as large jumps in temperature conditions.

- Frost resistance. Such a brick product can be used for construction in northern latitudes. The lowest possible temperatures cannot lead to destruction, the value of the freeze-thaw cycles is in the range of 50 to 100.

- Waterproof. Constant contact with moisture will not cause any harm to the foot of a building made from such building materials, because clay practically does not absorb moisture.

- Ease of maintenance. Unpretentious material that does not require special conditions. You can clean it with a regular brush with water.

The use of clinker bricks is quite wide, mainly these are structures that must meet high strength under constant loads. Clinker can act not only as a facing material that provides wall protection, but also be used as a decorative element. For example, you can. They decorate columns, windows, doors, he found his application in restoration work. Clinker production technology allows to obtain products of different colors by adjusting the firing process.

Solid brick for plinth

This type is used not only for the basement, it is widely used for cladding, laying the foundation, building room partitions and basements. Often solid blocks are used for construction load-bearing structures columns, partitions, walls in industrial and civil construction volumes. For production, environmentally friendly raw materials are used - red clay. (Here you can learn more about) The manufacturing process of a hollow ceramic block provides for the formation of voids, the volume of which in total should not exceed 13%. The final annealing is carried out at a working temperature of 1000 ºС.

The process of laying the base with a solid red brick

Using this technology, you can achieve the following parameters of a brick block:

- the strength of the ceramic product in bending and compression;

- moisture absorption from 8% when changing weather conditions;

- porosity, providing excellent engagement of the brick block with the mortar;

- high frost resistance;

- fire resistance of ceramic blocks;

- resistance to temperature fluctuations;

- masonry from a solid brick product has a beautiful appearance and does not require special skills;

All these requirements will be met only in such a high-quality building product:

- with exact overall dimensions 250x120x65mm;

- an ideal surface without dents and bulges, with even ribs and flat side surfaces;

- the value of the mass of the ceramic product should fluctuate within 4.3kg

- the presence of lime and stone in the composition of the ceramic block is unacceptable;

- when tapped, a good block should sound loud;

- the color of the finished ceramic product should be red-brown;

Important point! If the manufacturer offers you a solid brick block in black or dark brown, immediately refuse to purchase such material. This parameter indicates the poor quality of clay and a violation of production technology.

Plinth layout diagram

The disadvantage of a solid brick product is that it gives off a large amount of heat, so it is undesirable to use it to build the entire wall of the structure. Lined walls from this building material require either a large thickness or additional insulation.

Calculation of consumables for the construction of the basement

We decided on the choice of material, with regard to laying the basement, you first need to calculate the amount of basement bricks that you need.

You can calculate the required number of raw materials using a special service on construction sites, but you can calculate the material consumption on your own.

To begin with, there are some important factors to consider.:

- the basement bears the load of the entire building;

- perceives mechanical influences;

- protects from atmospheric precipitation, as well as from the absorption of moisture directly from the ground;

We lay out the base on the foundation

If the base is low, then. Experts suggest making the foundation of the highest possible dimensions, relative to the height of the snow cover, over the past ten years. Houses with high footings look more solid and solid and will protect the walls of your building as much as possible.

Let's get started with the calculations, for this you will need the following dimensions:

- The length of the perimeter of the house is determined by the sum of the dimensions of all the outer walls.

- The height of the plinth to be laid.

- The thickness of the basement structure, which depends on the scope of your structure. But the minimum should be - half a brick block.

- The size of the basement brick itself (for the calculation we will use clinker brick with dimensions of 250x120x65).

There are two ways to calculate the amount.

First option

- We calculate the volume of the basement masonry. To do this, we multiply the length of the perimeter of the house by the height and width of the planned foot.

- We calculate the volume of a single block.

- We carry out the division of the masonry volume by the volume of one unit. And we get the amount of the necessary material.

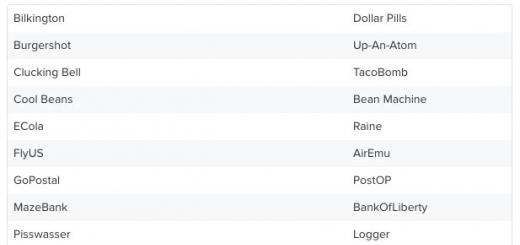

Material calculation table

For clarity, consider an example:

We calculate the basement structure with a height of 0.75 m and a width of 1 brick (0.25 m) for a house with dimensions of 12x15 m.

- The perimeter length is 12+15+12+15=54 m.

We calculate the volume of the basement masonry 54 * 0.75 * 0.25 \u003d 10.125 m³.

- We calculate the volume of a single block 0.25*0.12*0.065=0.00195 m³.

- We calculate the required number of blocks 10.125 / 0.00195 = 5192.3 pieces, we get 5193 pieces.

If there are openings in the base, door or window, you need to subtract the value of their volumes from the total number. For example, the size of the doorway is 0.9x0.75, the laying is again in one brick. We calculate the volume of the opening 0.9 * 0.75 * 0.25 \u003d 0.168 m³.

From the total volume of 10.125 m³ we subtract the resulting number 0.168 m³, and we get the value 9.957 m³. If there are many window and door openings, subtract their total volume.

IMPORTANT! Always buy building materials with a margin, taking into account possible marriage or damage during transportation.

Second option

Based on the calculation of the number of bricks in one row:

- We calculate the value of the number of units in the chain. To do this, we divide the value of the perimeter by the size of the block width (this applies to laying the base in one brick).

- We calculate the number of rows. To do this, we divide the height of the base by the height of the ceramic block.

- We multiply the number of rows by the number of units in one chain.

Example :

- We determine the number in the chain, which is equal to 54 / 0.12 = 450 units.

- We calculate the number of chains 0.75 / 0.065 = 11.5 pcs.

- We calculate the number of bricks 450 * 11.5 \u003d 5192.3; round up and get 5193 units.

Qualitatively laid out plinth photo

In the end, we get that for laying a basement 0.75m high, half a brick wide, with a house size of 12x15m. You will need 5193 bricks. These two calculations are simplified methods because we do not take into account the thickness of the seam between rows and bricks (its optimal value is 10 mm). In the refined calculation, this parameter must be taken into account. You can calculate the approximate amount according to your actual cap data, but if you still have doubts, check yourself with a calculator on the Internet.

Read more about here.

The plinth is a very important part of the design, so it is desirable:

- the use of reinforced mesh with the frequency of its laying - four rows;

- refuse to use cracked products;

- dressing and diligently fill the seams with cement mortar.

Others that can be used when laying the base.

Plinth laying video: