Pile foundation, how to insulate, what materials to use for this. And let's start with the question: what is a pile screw foundation and why it needs to be insulated.

The basis of the house, made using metal piles twisted into the ground, is called pile screw foundation. This technology has been used for a long time, only slightly changed over time. For example, earlier, wooden poles impregnated with various anti-corrosion compounds could be used as piles. This was necessary to increase the service life of the structure.

Technology developed primarily for areas with swampy terrain or on heaving soils with unstable soil. The advantage of using a pile foundation is that the weight of the house is transferred through the piles to the lower soil layers, which are much denser than the upper ones. Thus, the risk of destruction of the building is minimized.

At present, to organize the foundation for this technology piles are used, at the end of which there are blades, resembling a thread on a self-tapping screw, it is for this reason that the foundation is called pile-screw. For the installation of such piles, special equipment can be used or they are twisted by hand.

The screw foundation can be classified according to the height of the grillage. The grillage is the first crown of the foundation, which rests directly on the piles, in some cases, it is also called the strapping.

Rostverk happens:

- Short, is installed below ground level, i.e. the pile is completely in the ground. According to this principle, a pile-strip foundation is arranged, which outwardly cannot be distinguished from a conventional strip foundation.

- Tall when the grillage is at a certain distance from the surface of the earth.

- Intermediate, in this case, the grillage is located on the very surface of the earth.

The answer to the question why it is necessary to insulate the foundation on screw piles is that the space under the floor of the building is blown by the wind and no matter how the floor is insulated, it will not be as effective as if it is used together with the insulation of the screw foundation.

An insulated foundation is a guarantee of underfloor heating and significant savings on heating.

Insulation of a pile grillage foundation with a low grillage level

Warming strip-pile foundation can be carried out on the same principle as a conventional strip foundation due to the fact that it also goes deep into the ground and is made of reinforced concrete. This means that it is possible to use both sheet insulation for a pile foundation, and loose, and additionally insulate the structure with a warm blind area.

The insulation of the pile foundation grillage should begin with the marking and preparation of a trench with a width slightly more than the thickness of the insulation, a depth of 5-10 cm below the location of the bearing platform of the piles under the foundation.

At the next stage, it is necessary to clean the surface of the base and mount the insulation from moisture penetration, after which you can proceed with the installation of the insulation. To do this, you will need to have fasteners, mounting foam or other adhesive composition. Dowels for insulating materials are optimally suited as fasteners, or they are also “mushrooms” in the slang of installers.

Do-it-yourself insulation and finishing of the pile foundation

If it is necessary and at the same time to improve the appearance of the basement, you can apply the technology of insulation using bulk materials, together with basement thermal panels.

The algorithm for this type of insulation is as follows:

- A trench is being prepared with a depth just below the pile pad and a width of 0.5 to 1 meter.

- Sand filling is being done.

- The trench is filled with insulation, a little short of the ground level, 5-10 cm is enough.

- Thermal panels are installed, they need to be deepened a little into loose insulation and secured with dowels.

- The blind area is poured.

Insulation of a pile foundation with an intermediate grillage

Insulation of this type of foundation is best done using thermal panels, since it is not necessary to significantly deepen the insulation into the soil. Thermal panels can be mounted both directly on the surface of the foundation, and on a pre-prepared crate.

Insulation of the basement of a pile screw foundation with a high grillage

A pile-screw foundation with a high grillage is the most common foundation of this type. Depending on the design, the grillage can be at different heights. At the same time, it is simply necessary to protect and insulate the space under the house. For this, technology is used to create false base.

Such a plinth can be made of brickwork, or using a wooden frame on which the insulation is mounted.

False brick plinth

The organization of such a basement for a house on a pile-screw foundation is not the most popular way to solve the problem. Firstly, brickwork turns out to be quite expensive, due to the fact that it is necessary to use facing bricks, cement, crushed stone and sand to make a pillow.

If you save on brick and use a cheaper one, then you will have to spend money on exterior decoration. Secondly, to hide the piles, you need to take out the brickwork so that they remain inside, which is not always possible to do.

The process itself looks like this:

- A trench is being prepared for the arrangement of a sand cushion, its average depth is about 20 cm.

- Crushed stone is poured and rammed, then sand.

Tip: for better compaction of the sand cushion, it can be poured with plenty of water and allowed to dry before laying.

- Brick is being laid. Masonry is used with an offset of half a brick, i.e. standard.

After the masonry is ready, it need to insulate the sides. To do this, it is more convenient to use sheet heaters. It can be polystyrene, or analogues. Insulation with expanded clay will require additional costs for the installation of formwork. One of the best options is to apply from the inside of such a base, it will reliably protect the structure from the penetration of cold.

Insulation of the base of the pile foundation

Panel plinth or it can also be called a frame, which will reflect its essence much more fully, it is made according to the following scheme:

- Is being done double binding of all piles from the outside. With a high height of the grillage, the number of turns can be increased. The binding can be both metal and wooden. Metal, as a rule, is fixed for welding, this is the most popular way, as for wood, you can weld guide corners on piles and fix the strapping with wood screws. The second option is to use metal clamps.

- At the next stage, you can install thermal panels, or sheet insulation. If it is planned to insulate the base with the help, then the strapping must be sewn up with tessellate, after which the insulation should be sprayed on both sides.

When using non-insulated panels to create a plinth, it can be covered with soil from the inside, but it is better to use expanded clay for these purposes. At the same time, do not forget about the waterproofing of the grillage.

When using non-insulated panels to create a plinth, it can be covered with soil from the inside, but it is better to use expanded clay for these purposes. At the same time, do not forget about the waterproofing of the grillage.

Benefits of a panel plinth obvious, this is the simplicity of design, speed of installation, a large number of options for insulation, both from the inside and from the inside.

If you plan to independently manufacture a false base, you will need the following tools and skills to work with them:

- welding machine for welding fasteners to piles;

- "Bulgarian" for cutting metal corners;

- drill for drilling corners;

- a screwdriver for mounting self-tapping screws that fasten the insulation;

- building level for leveling the strapping along the horizon;

- chainsaw for cutting wood trim.

conclusions

The pile-screw foundation with a high grillage is popular due to its low cost and high practicality. Its disadvantage is the ventilated underground space.

To protect the house from the penetration of cold and just to give it beauty, the technology of creating a false base is used. You can make it with the help of insulated brickwork, but it is better to use the technology of an insulated panel base. Compared to masonry, panel plinth is much cheaper and more efficient.

Useful video

How to close the basement of a pile foundation with a brick:

In contact with

The foundation on screw piles differs from traditional types of foundations in that the foundation of a house or other structure is raised above the ground to a certain height. As a result, there is always open space under the building, and the scheme of warming the house from its lower part is fundamentally different from the warming of a house standing on a monolithic foundation. In some cases, the foundation itself on screw piles requires separate insulation.

1. The role of foundation insulation on screw piles

The difference between the foundation on screw piles and other types of foundations is, among other things, that the base of the building installed on it is at a certain height from the ground. This is because:

- The surface of the building plot may have a slope

- Full penetration of the pile is impossible due to the peculiarities of its design and installation.

- The space between the soil and the pile prevents the interaction of the foundation strapping with the soil

In connection with the raising of the foundation under the house, there remains a space free for the penetration of air currents, precipitation and melted snow. In winter, snowdrifts can even be applied under the house.

Thus, the foundation of the house is not protected from low temperatures, especially since the coldest air masses accumulate precisely at the soil surface. In addition, the foundation of the house does not allow sunlight to penetrate into the sub-house space - as a result, it is always damp below.

The only positive factor from this point of view can be considered good ventilation of the space under the house. Sometimes, with good insulation of the lower floor of the house, this circumstance even plays a positive role - many developers prefer not to insulate the supporting foundation. Sometimes this is almost impossible - when the slope of the construction site is significant and some of the piles protrude high above the ground.

However, in most cases, the space under the house is recommended to be insulated. In this case, we can talk not so much about the insulation of the foundation (in the case of installing screw piles, it is practically not necessary), but about the insulation of the house as a whole.

A frame house, namely, such residential buildings are most often built on pile-screw foundations, has the design of a kind of thermos. The outer shell of the frame walls consists of 70-75% insulation. Insulation of ceilings and roof rafters is carried out similarly to that for monolithic houses (made of bricks, blocks or logs). Therefore, the insulation of the frame house from below plays a special role. In monolithic houses, this problem is not so acute, since their foundation, made in the traditional way of reinforced concrete, is adjacent directly to the surface of the earth.

Thus, speaking of insulation pile screw foundation we can talk not only about protection from the cold of the sub-house space, but also about additional insulation of the lower floor of the house.

2. Various options for insulating a pile-screw foundation

Based on the foregoing, we actually have two options for warming the lower part of the house:

- Creation and insulation of the original walls of the basement space under the house

- Additional insulation of the lower ceiling and floor

It is obvious that the lining of the basement of the foundation in the first case is accompanied by its insulation. We talked in detail about the basement finish of the foundation on screw piles here. The device for lining the basement, and accordingly its insulation, can be carried out in two ways:

- By autonomous design around the entire perimeter

- On a crate mounted on screw piles

Thus, we can say that the lining of the basement is accompanied by its simultaneous insulation.

The first method includes the installation of brick or concrete (or other monolithic) walls with a height corresponding to the height of the pile above the ground.

Brick walls are laid out around the entire perimeter of the building, or a formwork is created where concrete is poured, or beams or logs are laid. Such a wall may not even be rigidly connected to the supports.

Sometimes the creation of a monolithic plinth cladding completes the insulation of the foundation. Indeed, a brick wall, and, moreover, a log wall already has certain properties of heat preservation, not to mention protection from the penetration of rain, snow or wind. After all, brick or other monolithic materials serve as the main thermal protection in monolithic structures. True, there is one nuance here - the houses are heated from the inside, in contrast to the space under the house. In most cases, brickwork plays a more decorative role than an insulating one.

The second, more optimal option for frame houses can be considered the simultaneous lining of the basement and its insulation with sheet material. We will consider it in more detail.

3. Warming on the facing plinth

The order of insulation of the cladding in the general case is as follows:

- Installation on piles of supports for crates

- Lathing construction

- Fixing cladding and insulation

As a rule, the crate on the screw piles is made of wooden boards - it is most convenient to fix the cladding sheets on them. This requires solving the problem of fastening wooden elements to pipes.

A good way is to install special brackets and a metal profile on the piles, to which the batten boards are screwed. With a large pile pitch, vertical wooden posts can be installed. Lathing for extended sheet materials, such as metal or vinyl siding, is usually placed in the form of boards parallel to the ground with a counter-lattice of bars. Sometimes, for example, in the case of cladding with corrugated board, only vertical bars are enough.

Obviously, you first need to fix the insulation so that it is protected from the outside by facing boards.

As a heater, monolithic slabs are usually chosen. In the case of using mineral wool, they must be fixed on both sides, which is inconvenient due to the low height of the base and the difficulty of working from the inside of the perimeter.

Today, the most popular material for insulation of foundations is foam. It has a dense structure, like expanded polystyrene (polystyrene), is lightweight, perfectly cut and easy to install. Actually, penoplex is extruded polystyrene foam. It has higher thermal insulation properties than conventional foam, although it costs more. The thermal conductivity of foam plastic is 0.029 W/mk, which is lower than that of foam plastic (0.038 W/mk). A foam sheet with a thickness of 30 mm completely replaces a sheet of expanded polystyrene with a thickness of 50 mm in its properties. In addition, foam plastic does not allow moisture to pass through, unlike more loose foam.

Other materials are widely used for insulation:

- Liquid penoizol sprayed onto a solid crate

- Foamed glass produced in blocks.

Sheet insulation is fastened either with self-tapping screws, or simply glued to the crate.

After fixing the insulation boards, it is necessary to protect the joints from the occurrence of cold bridges - that is, glue them with adhesive tape or, best of all, foam them with liquid sealant.

It should be noted that non-extruded foam is not very good at low temperatures. Its pores can accumulate moisture, and frozen water gradually destroys the material. Extruded foam in this sense does not suffer from low temperatures.

When installing insulation, one should not forget about the ventilation of the space under the house. Be sure to leave ventilation holes, called breathing holes. In addition, it is recommended to leave a gap (5-7 cm) between the bottom of the cladding and the ground surface. This is necessary in order to minimize the effect of frost heaving of the soil. When finishing, this gap is closed with a blind area.

From the inside, it is also necessary to apply a fine metal mesh to the insulation, which will protect the material from rodents.

4. Insulation of the foundation from the inside of the cladding

Above, we cited the case when the insulation of the basement space is already carried out when the house is built. As noted, it is not very convenient to carry out work from the inside, so the insulation is placed on the crate from the outside. This eats up part of the external space, and it is quite difficult to attach the facing plates to the insulation. Mounting the siding directly on the crate will be much stronger.

But then the insulation must be fixed to the same crate from the inside.

This is possible if the insulation of the foundation is carried out before the construction of the house. In this case, the insulation can no longer be decorated in any way - neither plastered nor covered with cladding. The only thing - do not forget about the net against rodents.

5. Warming of the lower ceiling and the floor of the first floor

The process of warming the lower base of the house was covered in detail here. It simply boils down to the creation of the so-called "pie", consisting of

- Vapor barrier films

- Waterproofing

- insulation

The peculiarity of floor insulation in a house standing on screw piles is that the lower floor is at a certain height above the ground. This means the need to create a solid foundation above the foundation strapping. If the floor screed, installed close to the ground, can be carried out immediately, then in this case it is necessary to create a rough flooring.

Most often this is done as follows:

- Support logs are installed on the foundation strapping

- Subfloor boards are laid on the logs

The lower floor of the house formed in this way is insulated according to the standard method.

6. Conclusion

Insulation of the pile-screw foundation is important in the heat preservation of the whole house. You can do it yourself, but this work requires some effort and skill - after all, any mistake or negligence can lead to a deterioration in the comfort of your home in the future. In addition, some mistakes can lead to premature aging of the house - due to foci of corrosion, due to temperature changes, and so on.

Specialists of the company "K-DOM" are ready to carry out all the work - both for the installation of screw piles, and for the construction of houses of any complexity. Construction technologies have been developed for a long time, and your house will keep warm in winter and cool in summer.

Work is carried out on the surface of the grillage. Roofing material is used as a waterproofing material. It is laid in the gaps between the grillage and the building itself.

The surface of the piles and the grillage must also be treated with a mastic that does not allow moisture to pass through.

- Installation of thermal insulation. After choosing the material for work and calculating its parameters, you can proceed directly to the installation of the thermal insulation layer.

With the help of an adhesive, sheets of heat-insulating material are applied around the entire perimeter of the grillage and along the surface of the piles.

It is necessary to firmly fix the waterproofing materials. For this, mounting foam is used, which is laid in the seams between the material plates.

- Conducting exterior cladding. Various types of decorative tiles are used as materials. So, you can use materials that imitate brick, natural stone. For cladding, you can use marble, granite, porcelain stoneware. As a budget option, a profiled sheet or siding panels are used.

The lining of the base is necessary to protect it from external environmental influences and damage to the surface of the thermal insulation.

Creating a decorative plinth

Technology

How to insulate a pile screw foundation by creating a basement? The technology can be divided into several stages:

- The choice of material (the sequence of further actions depends on this decision);

- Creating a frame (what it will be depends on the type of insulation);

- Work with joints;

- Products.

Let's move on to material selection.

materials

The material for insulating the base of the pile screw foundation will be in contact with the ground and therefore must have sufficient hydrophobicity. Most often, extruded polystyrene foam is used for such purposes. The material has a low thermal conductivity of 0.04 W/m2. In addition, this insulation has zero vapor permeability - it did not let moisture into the frame. However, for the sake of fairness, we can say a few more options.

- Polyurethane foam (PPU);

- Penoizol;

- Foam glass;

- Mineral wool with high rigidity.

The latter is rarely used, it needs steam and wind protection and has no special advantages for use near the ground.

Since polyurethane foam is applied by spraying, it needs a solid frame, made for example from a board.

Also, brickwork is also used, but this is more likely not a heater, but part of the frame, which means more about that later.

Mounting

In the "Technology" section, the second item is the creation of a frame. If the frame is brickwork, then the wall is built according to the usual principles of construction and insulated like a brick wall. But, this method is rarely used, because it is much more expensive. More often, a frame-crate is erected.

- A guide is attached to the grillage along the entire length of the wall or is joined from several elements;

- The lower guide is attached to the blind area;

- After that, with a step along the length of the plate, transverse guides are attached;

- Expanded polystyrene sheets sit on the adhesive foam from the inside of the profile;

- From the outside, a profiled sheet, facing panels or DSP sheets are attached;

- All gaps between the XPS boards are filled with the same foam.

Having done all these steps, you will significantly insulate the space under the house. In addition, the frame with insulation will serve as wind protection. Before that, the wind was walking between the piles. But, now in any case, the space must be ventilated. Therefore, usually in two places with the help of a grinder, air is made, on which a ventilation grill is put on or special opening doors are made

Don't forget about it important point at the stage of warming.

Carrying out basic calculations

Before starting work, a preliminary analysis should be carried out. To obtain accurate calculations on the parameters of the heat-insulating layer, to calculate its effective thickness, the following measurements must first be made:

- Building perimeter

- Room area

- Area of living rooms

- The degree of load on the base

- Parameters of used screw piles

- Number of people living in the building

- Features of the local climate

- The level of freezing of the earth's surface

Only after taking into account all the above factors, it is possible to accurately calculate the required amount of heat-insulating material and the thickness of the layer used.

Internal floor insulation on a pile foundation

Floor insulation on the basis described is carried out in several stages. vapor barrier for the floor is laid from the outside over the entire area. A polystyrene foam insulation is installed on top, which is sheathed with boards. Such a floor can be used as a finished basement ceiling.

For hydro and wind protection, you can use modern moisture-proof membranes. They are simple and quick to install, but the cost of multifunctional products can scare you away.

All elements of a wooden house on stilts are treated with an antiseptic composition.

It is important not to forget about the vapor barrier for the floor. It can be a polyethylene film, which is laid on a layer of heat-insulating material

When installing steam and heat insulation, no gaps should be left between individual elements. This can lead to the formation of cold bridges. Insulation under the floor in this case can quickly collapse during operation. For additional protection of the interior from the cold, you can use chipboard, floorboard or plywood sheets, which do not conduct heat well.

Plinth made of piece materials

Brick, building blocks (aerated concrete, foam concrete and tudu), foam glass are suitable for the construction of the basement. In the latter case, the material itself serves as a good heat insulator.

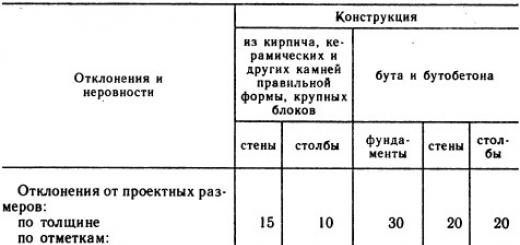

Under the masonry of piece materials, it is required to create a strip foundation of reinforced concrete. To do this, a trench about 20 cm deep is dug around the perimeter of the house. If the house stands on a slope, in order to reduce the material consumption of the structure, the strip foundation is made stepped, keeping the surfaces horizontal.

After the concrete has set, lay out a wall of piece materials. If we are talking about bricks, then for a low-height basement, a half-brick masonry thickness is enough. For a full-fledged basement floor, it is required to prepare a more solid foundation and lay out walls one and a half bricks thick.

It is important to take care of high-quality waterproofing between the concrete foundation of the basement and masonry, as well as between masonry and grillage - horizontal supports between piles that support the wall structures of a wooden house. For waterproofing use rolled bituminous material - roofing material or its analogues, laying in two layers

Floor insulation

To achieve the maximum effect from the insulation of the foundation, it is also necessary to insulate the floor. Therefore, in the end, I will tell you how this procedure is performed:

- First of all, you need to lay a subfloor. You can do it in two ways - hem sheets of plywood or other sheet material from below to the logs or fasten the slats (rough bars) on the logs from below and lay the sheets on them, as shown in the diagram above;

- then a waterproofing film is overlapped on the logs and the subfloor. For greater tightness, the joints should be glued with adhesive tape;

Floor insulation in a frame house on piles with mineral mats

- further, heat-insulating material is laid on the waterproofing. It is best to use mineral mats for these purposes. It should be noted that the insulation must fit snugly against the logs so that there are no cold bridges;

- then another layer of thermal insulation is laid on top of the insulation.

Now you can lay boards or other flooring on top of the log. Thanks to all these manipulations, the floor in your house will remain warm even in the cold season.

Warming technology

Creating a pick-up - the very design that will replace the base.

You can carry out thermal insulation of the pile-screw foundation on your own. All that is required is accuracy and quality materials. The essence of the work is to create a solid structure that will serve as a base. It is this building that will be insulated.

The work order is as follows:

- Waterproofing grillage - jumpers connecting piles into a single structure. This stage is mandatory regardless of the material from which the main structural elements are made. At the joints of the grillage with the wall and piles, a roofing material is laid. Metal parts are coated with water-repellent mastic or liquid rubber. Wooden structures are treated with an antiseptic. Read more about the insulation of the foundation of a wooden house here.

- Creating a pick-up - the very design that will replace the base. It is made of brick, wood, or simply creates a metal frame on which facing panels are attached. The fence will protect the insulation and the space under the house from wind, rain, snow and other adverse events. All further work on insulation is carried out from the inside of the partitions.

- Heater installation. Styrofoam, foam plastic, any other moisture-resistant material can act as thermal insulation. The plates are mounted on glue with careful insulation of the joints. You can use foam glass or airgel - these are more modern materials that do not require additional waterproofing. Ideally, it is better to apply polyurethane foam to the entire surface of the intake along the perimeter. This will strengthen the structure, provide its wind and moisture protection. And it will be more difficult for rodents to get through such a barrier.

- Powder basement structure. From the inside, the pick-up is sprinkled with gravel, crushed stone, and earth.

The use of sprayed polyurethane foam will be more effective.

In case of extreme financial hunger, the entire space between the base of the foundation and the surface of the earth can be covered with soil. It is cheap and easy, although ineffective.

Before you insulate the foundation on piles, you need to correctly assess your strengths. You will have to work in cramped conditions. The material is mounted from the inside, and if the distance between the soil and the grillage is small, then it is unlikely that it will be possible to glue the sheets accurately and accurately. The use of sprayed polyurethane foam will be more effective. Firstly, you don’t have to climb under the house yourself - c. Secondly, such thermal insulation is guaranteed to be even, seamless. All gaps between structural elements will be carefully sealed.

PPU from Ecotermiks is considered the best among other heaters. We recommend watching the video on the insulation of the attic foundation below:

How to insulate the foundation of the house from the inside

The most popular heaters on our market today are mineral wool, as well as polystyrene foam and polystyrene foam. Mineral wool, due to its ability to absorb moisture, is considered a lower-quality insulation for the foundation of a house from the inside. When using it, an additional waterproofing device is required. The relatively new foam material has a higher thermal protection coefficient and strength compared to foam plastic, but its price is also significantly higher.

After warming, the space under the grillage is filled with light and warm material - expanded clay, which significantly reduces the ventilation of the underground. Sometimes, instead of expanded clay, ordinary earth is covered, but the thermal protection of this method is not so effective, although it is much more economically profitable.

Waterproofing device

If you do not take all the measures for a competent waterproofing device, then the metal from which all structural elements are made may corrode. Wooden elements can be affected by fungi and rot.

The loss of the characteristics of piles or wood can significantly affect the life and durability of the building.

In order to secure the structure, one of the waterproofing materials is laid at the point of contact between the pile elements and the grillages. For example, it can be a layer of roofing material. It also needs to be placed on those faces of the grillage that are joined to the wall of the building.

Following this, the entire foundation is treated with waterproofing mastic, and the wooden parts with an antiseptic.

After a week, after the final absorption of the solutions, the next stage is carried out - the insulation of the foundation.

Waterproofing works

Do not forget that the waterproofing work of the screw foundation is one of the stages in the arrangement of thermal insulation. They are carried out in order to prevent moisture from entering the joint between the grillage and the piles themselves.

If waterproofing is not carried out, then the foundation of the house will not withstand for a long time. This is due to the fact that its metal parts will corrode, and the wood will begin to rot. This can be prevented by means of such a well-known material as roofing material. It should be placed at the junction of the ends of the piles with the beginning of the grillage. They should also cover the top of the grillage itself - where it comes into contact with the wall.

Also, waterproofing a screw foundation involves applying special mastic to all metal parts. At the same time, wooden structures are impregnated with a solution that prevents the process of decay in a humid environment. Only after these substances have dried, you can start warming the pile foundations of the house.

Strip foundation

First, they dig a trench to the very bottom of the foundation. Its width is 80-100 cm, since the blind area is also insulated at the same time. If the foundation is of a recessed type, then the first 40 cm in depth they dig a trench to the width of the blind area, and then, to save energy, you can make it 50 cm wide.

If the house was built some time ago, then cracks may appear on the concrete. They are covered with a mixture of cement with building glue, if the cracks are small. Larger damages are sealed with cement mortar.

The next step is waterproofing. To do this, the surface of the foundation tape is covered with bituminous mastic, on which roofing material is glued. The sheets are glued overlapping, the seams are additionally coated with mastic. More modern roll materials are also used, such as self-adhesive roll waterproofing.

After that, the insulation is glued. Although penoplex is often attached to dowels, it is still better to give preference to glue or liquid nails - they do not violate the integrity of the sheets. How to insulate the strip foundation with polystyrene foam, look at the video:

The joints between the sheets are foamed with liquid foam.

After installing the insulation, geotextiles are glued to it. It will reduce the effect of soil heaving on the heat-insulating layer.

Next, the trench is filled up to the level of the blind area. Sand and small gravel are poured under the blind area with a layer of 0.15-0.2 m, the pillow is carefully rammed. This layer will protect the blind area from the loads arising from the movement of the soil. A layer of dense insulation is placed on top. The same penoplex is suitable due to its resistance to compressive loads. Concrete is poured from above, it can be additionally reinforced with a mesh.

Attention! To reduce the effect of frost heaving, a layer of insulation is placed at the level of the sole of the foundation. The most effective combination of foam insulation to the level of the walls in combination with the insulation of the blind area at the level of the sole.

.

basement insulation

Insulation of the basement of the pile foundation allows you to make the interior of the premises more comfortable. First you need to build a base, and then proceed with the insulation by any of the existing methods. The device of the base is allowed in certain ways. You can lay a wall that will cover a row of screw piles. The height of the wall should be equal to the length of the line from the blind area to the lower belt of the house strapping.

You can arrange a pickup, which is a fake plinth. It will be arranged on a frame base and will have an external cladding. If you chose the first method, then the laying must be done in half a brick. Products will be red ceramic, as they are most resistant to high humidity.

To begin with, you must prepare the foundation, for which a trench is dug around the perimeter of the building. Depth and width will be 0.3 and 0.25 m, respectively. The bottom is well leveled and filled with coarse sand. The layer thickness should be 10 cm. After that, the sand mixture is compacted and moistened.

A reinforcing cage of longitudinal and transverse rods is laid on such a base, after which the concrete mixture is poured. After the concrete mortar has hardened and gained strength, you can proceed to the construction of a brick wall.

pile foundation

How to insulate the foundation of a wooden house on stilts? For a pile foundation, as well as for a column foundation, a fence is constructed - an imitation of a basement, closing the space between the piles. This will reduce heat loss to some extent. For effective thermal insulation of a pile foundation, you need:

- build a plinth

- insulate it inside and out

- insulate the floor.

You can build a thin brick wall around the perimeter, or you can use slab materials that are attached to the crate. If the option with a brick wall is chosen, a shallow concrete strip 20 cm thick must be poured on which the wall will be built. It is not necessary to use ceramic bricks, you can take foam blocks or foam glass.

Important! Do not make the space under the floor airtight. After the device is taken, it is necessary to make air in it - ventilation holes measuring 10-15 cm

They are placed evenly on all sides of the house so that they are opposite each other.

For fastening panels or slabs, a crate is made of a metal profile or wooden bars. As an outer skin, for example, DSP can be used. There are already insulated facade panels that perform a decorative and heat-insulating function.

A shallow trench is dug under the skin, where a layer of sand (2-3 cm) is poured, expanded clay is poured on it, and the trench is covered with earth from above, so that there is no gap between the soil and the skin.

The video shows the device and the insulation of the false base:

To insulate the pile foundation, use

- styrofoam,

- Styrofoam,

- foamed glass blocks

- liquid penoizol (carbamide foam).

Most often, the first two options are used. Foamed glass is too expensive for a private house, and liquid penoizol requires special equipment or the work of specialists, which is also expensive. With your own hands, it is easier to insulate the foundation in a wooden house with polystyrene foam or polystyrene foam from the outside. The main thing is that the material does not absorb water, so mineral wool is not suitable here. The foam is glued to the adhesive foam, for reliability, additional wooden planks can be used, which are attached with self-tapping screws to the crate through the foam.

Important! It is advisable to attach polystyrene foam or polystyrene to the guides, and not between them. In this case, there will be no gaps and cold bridges, since the thermal conductivity of wood, and even more so of metal, is greater than that of polystyrene.

It is possible to insulate the pile foundation with polystyrene foam or EPS from the outside or from the inside. If this is done from the outside, then the insulation is attached before finishing. If the finish is already attached to the base, for example, if these are facade panels or DSP boards, then the insulation is mounted from the inside.

Floor insulation

To insulate the floor in a wooden house on a pile foundation, I usually use mineral wool, basalt wool, polystyrene foam, polystyrene, liquid heaters.

Thermal insulation is done during the construction process and floor installation as follows:

- They make a draft floor on which the insulation will lie.

- A vapor barrier and windproof layer are first placed on the crate.

- Then put the heater.

- Vapor barrier and waterproofing are placed on top.

- After that, a finishing floor is constructed.

The mineral wool layer should be at least 10 cm. If it is necessary to put cotton wool in two or more layers, this is done in a checkerboard pattern (so that the seams do not match). The video shows floor insulation in a house on a pile foundation.

For waterproofing, you can use glassine, polyethylene, isospan, wind-moisture protective film. Polyethylene is the cheapest option, but it's not the best.

Important! In a house made of wood on a pile foundation, it is imperative to treat all wooden floor elements with an antiseptic.

The insulation of a columnar foundation differs little from the insulation of a pile foundation; the same materials and techniques are used.

How to insulate a pile screw foundation with your own hands

The process can be divided into 5 main stages: waterproofing a metal structure, making a frame for fixing thermal insulation, installing insulation with a waterproofing film if necessary, fixing decorative panels on the basement of a house, installing an insulated blind area around the perimeter of the house, backfilling with soil or expanded clay inside the foundation of the house. Let's consider these stages in more detail.

1. Waterproofing of the pile foundation

Regardless of the grillage material - wood or metal, thorough waterproofing is necessary so that moisture from the soil does not penetrate into the structure, leading to metal corrosion and wood decay. It is necessary to protect all parts of the structures where thermal insulation will be made with roll or liquid waterproofing. The tree should be treated with antiseptics, and the metal frame should be treated with bituminous mastic.

To create a heat-saving cladding between the ground and the facade of the house, it is necessary to create a structure that imitates the basement of the house. This design can be made from light brickwork on a shallow foundation. The brick base is insulated from the outside with foam or foam plastic boards and sheathed with siding or panels. You can create a frame from timber or metal rails.

2. Making a basement at home

A photo. Pile foundation insulation scheme

To make a brick basement, it is necessary to fill in a shallow reinforced foundation up to 20 cm. After the concrete has hardened, a red brick basement is laid out. The fastening of thermal insulation boards from the outside is carried out on the brickwork with mounting foam and glue for expanded polystyrene. The insulated brickwork of the pile foundation is sheathed with decorative panels imitating natural stone or brickwork.

The second method, a frame made of timber or metal, is a simpler and more inexpensive method. It consists in attaching horizontal guides to piles using bolts or welding. Thermal insulation plates are fixed between the guides, the joints should be treated with mounting foam. Further, decorative panels or siding are mounted on the rails from the outside. On our website you can calculate the thickness of the insulation for the base on a heat engineering calculator.

3. Thermal insulation of the basement of the house

Sheathing the basement of the house with pvc panels

When self-insulating the facade with mineral wool or the basement of a house on a pile-screw foundation, a distance of 10-15 mm less than the width of the insulation should be left between the guides. In this case, the mineral wool will sit tightly between the guides, leaving no cold bridges. Mineral wool should be closed with waterproofing, we remind you that you should put the vapor barrier on the insulation on the right side.

When insulating the foundation on screw piles with foam or expanded polystyrene, the seams between the plates should be foamed with mounting foam. If the characteristics of the foam plastic guarantee that the material will not absorb moisture and will not suffer from rodents, then the foam boards should be protected from rodents and possible mechanical damage. You can veneer the insulation on the basement of the house with vinyl or metal siding.

4. Fixing decorative panels

For lining the basement from below, it is necessary to fix the starting profile for siding along the entire perimeter of the house. Then, from the bottom up from the starting profile, siding panels or decorative PVC panels are attached. This facing material will protect the insulation on the pile foundation from precipitation, mechanical damage and the penetration of rodents. Do not forget about carrying out additional waterproofing of the facade under the siding.

5. Backfilling with soil or expanded clay

A photo. Vents in the basement of the house (vent holes)

From the inside, the insulated pile-screw foundation can be covered with soil or expanded clay - this will additionally insulate the underground space of the house. Outside the building, an insulated blind area should be arranged to reduce the freezing of the soil under the house and reduce the heat loss of the house during the heating season. On opposite sides of the basement, ventilation holes (vents) should be made, closed from rodents and insects with gratings.

Ventilation openings are used to remove moisture from the underground of the house; for the winter, the ventilation openings should be covered with rags. At the end of the material, we posted a video instruction from experienced builders on the issue under consideration, how to insulate the foundation on screw piles baths or a country house to remove all possible issues.

Insulation on the facing plinth

The order of insulation of the cladding in the general case is as follows:

- Installation on piles of supports for crates

- Lathing construction

- Fixing cladding and insulation

As a rule, the crate on the screw piles is made of wooden boards - it is most convenient to fix the cladding sheets on them. This requires solving the problem of fastening wooden elements to pipes.

A good way is to install special brackets and a metal profile on the piles, to which the batten boards are screwed. With a large pile pitch, vertical wooden posts can be installed. Lathing for extended sheet materials, such as metal or vinyl siding, is usually placed in the form of boards parallel to the ground with a counter-lattice of bars. Sometimes, for example, in the case of cladding with corrugated board, only vertical bars are enough.

Installation of the crate for basement insulation

Installation of the crate for basement insulation

Obviously, you first need to fix the insulation so that it is protected from the outside by facing boards.

As a heater, monolithic slabs are usually chosen. In the case of using mineral wool, they must be fixed on both sides, which is inconvenient due to the low height of the base and the difficulty of working from the inside of the perimeter.

Today, the most popular material for insulation of foundations is foam. It has a dense structure, like expanded polystyrene (polystyrene), is lightweight, perfectly cut and easy to install. Actually, penoplex is extruded polystyrene foam. It has higher thermal insulation properties than conventional foam, although it costs more. The thermal conductivity of foam plastic is 0.029 W/mk, which is lower than that of foam plastic (0.038 W/mk). A foam sheet with a thickness of 30 mm completely replaces a sheet of expanded polystyrene with a thickness of 50 mm in its properties. In addition, foam plastic does not allow moisture to pass through, unlike more loose foam.

Standard sheet foam

Standard sheet foam

Other materials are widely used for insulation:

- Liquid penoizol sprayed onto a solid crate

- Foamed glass produced in blocks.

Sheet insulation is fastened either with self-tapping screws, or simply glued to the crate.

After fixing the insulation boards, it is necessary to protect the joints from the occurrence of cold bridges - that is, glue them with adhesive tape or, best of all, foam them with liquid sealant.

It should be noted that non-extruded foam is not very good at low temperatures. Its pores can accumulate moisture, and frozen water gradually destroys the material. Extruded foam in this sense does not suffer from low temperatures.

When installing insulation, one should not forget about the ventilation of the space under the house. Be sure to leave ventilation holes, called breathing holes. In addition, it is recommended to leave a gap (5-7 cm) between the bottom of the cladding and the ground surface. This is necessary in order to minimize the effect of frost heaving of the soil. When finishing, this gap is closed with a blind area.

From the inside, it is also necessary to apply a fine metal mesh to the insulation, which will protect the material from rodents.

Scheme of insulation of the basement on piles

Scheme of insulation of the basement on piles

Perhaps the biggest mistake- remember the need for insulation after construction. In this case, it will turn out to be much less effective, most likely more expensive and time-consuming. There is also a chance to damage the foundation structure, which can lead to problems in the operation of the house or even its destruction.

Despite the fact that many heaters themselves are quite resistant to water, do not collapse from it, and sometimes do not let through at all, this does not mean that traditional waterproofing should be neglected. Protecting the foundation from moisture is the key to its long and safe operation.

- After completion of the insulation procedure for the basement of the building, it is necessary to withstand at least 7 days to strengthen it. Then you can proceed to install the waterproofing layer.

- Do not forget about the installation of ventilation. Ventilation openings must be strictly opposite each other with a step of at least 1.5 or 2 m.

- To prevent destruction and shift of the soil, do not move, move or try to unscrew the foundation piles. This can lead to its complete destruction.

- To strengthen the base and increase the level of its reliability and strength, a layer of reinforcing mesh can be laid.

- With a properly carried out procedure, the space inside the base can be used for various household needs (underground, shed, warehouse, storage space for homework, etc.). In this case, communications can be carried out into the room. Thus, you get an additional technical floor in your own home.

As you can see, the procedure for strengthening the pile foundation through its thermal insulation is available to almost everyone. It can easily be done by any builder. There is no need to resort to the use of specialized equipment and acquire additional theoretical skills.

Video. Foundation insulation on screw piles

New publications

- How to insulate a potato box on a balcony

- How to insulate a house from the outside and how inexpensively

- How to insulate the roof so that there is no condensation

- How to insulate the door in the apartment with your own hands

- How to insulate the facade of a wooden house with your own hands

New comments

- Stanislav. You know, theory is theory, but practice is needed in such things, a brother built a house for himself, they read wow together.

- Victor. Thanks for the article, very informative. However, about the correctness of the insulation of the foundation with mineral wool, I am strong.

- Igor Gennadievich. Great article. The entire technology of strip foundation insulation is described in detail and clearly. For.

- Aylis. Thank you for the article! We've had gaps from time to time. They ordered a specialist from Biplane, he came, did everything, for.

How best to insulate the foundation on piles

When choosing the best insulation option, it is necessary to be guided by regulatory indicators and the possibility of using all acceptable options.

At the same time, attention should not be diverted from the economic effect.

You can lay and insulate the strip foundation around the perimeter of the house on stilts. This will be a reliable choice. The rooms will be warm and cozy, but the process will affect the cost of the work. Alternatively, a shallow tape is poured. Thus, you do not have to spend money on complex work, and additional manipulations will protect the house from the cold.

- Izospan: universal insulating material

- How to properly waterproof the basement?

You can make piles sewn with any building material and cover the underground space with expanded clay. The option is inexpensive, but not entirely effective and is suitable for places with a low level of moisture in the soil.

In fact, there are many options with which you can insulate the pile base and it makes no sense to list each one. Over the years of using pile foundations in housing construction, specialists have developed their own “recipes” and suggest considering the following methods in this regard:

- External insulation relative to the perimeter of the building. The method is in demand if the fundamental piles do not rise too much above the ground. The process is concluded in the construction of the frame along the basement, the insulation of the basement space and the outer cladding.

- External floor insulation. If the house is on "difficult" ground, this option is the only one. In fact, floor insulation is carried out without basement finishing and .

- Combined insulation. In this option, a basement box is mounted outside, and insulation is also carried out in the basement.

On a note. The third option is preferable, but a little more difficult. When implemented, high thermal insulation is guaranteed and a decrease in the dependence of the house on cold weather.

Scheme of insulation of the pile base.

First of all, waterproofing. This is the basis of any work related to reducing the thermal load on the building material and the whole house as a whole. The purpose of creating waterproofing is to prevent the formation of condensate on piles, grillages and places where metal components come into contact with wood. Bituminous mastic is used in these cases. The composition is coated with all connections, and foundation pillars.

Do you need thermal insulation

Many builders want to save as much as possible on the work, so they often refuse such necessary measures as waterproofing and insulation.

When wondering whether it is necessary to insulate the foundation, one should consider its design in more detail.

The fact is that this type of basement is a system of pillars installed under the building. However, there is a lot of free space between the posts. This serves as a source of accumulation of cold air currents, which leads to a general decrease in the thermal conductivity of the entire building.

To avoid this, it is imperative to carry out the warming procedure. We figured out why to insulate the foundation. Now let's take a closer look at the object of work.

2 Technology of insulation of pile-screw foundation

All work on the insulation of the foundation begins after the grillage of the house is covered with waterproofing material. As a protection against moisture, special membrane films are used, or, if the budget is limited, an ordinary roofing material.

Insulation of a pile-screw foundation with foam plastic

Waterproofing covers both the upper part of the grillage, on which the walls of the building will be placed, as well as the lower and side parts, and the pile heads adjacent to the grillage.

To create an insulated false base with your own hands, you will need the following tools:

- Welding machine;

- Concrete mixer;

- Screwdriver as for insulation of the basement with polystyrene foam;

- Hammer, trowel, spatula, tape measure, clerical knife.

2.1 Creating an insulated brick base

The first option is more time-consuming, however, the result will be as reliable and durable as possible, while decorative panels are quite easy to damage.

To equip a brick basement under the grillage of the house around the entire perimeter of the building, it is necessary to dig a trench 20-25 centimeters deep, and a few centimeters wider than the size of the brick used.

The trench is poured with concrete, which, after hardening, will serve as the foundation for the brick plinth being created. Given that the depth of concrete is minimal, it is necessary to reinforce the base with reinforcement with a diameter of 10-12 mm.

Brick foundation base on screw piles

After the time required for the concrete to completely harden, we begin to build a brick base. The wall must be laid in sections of 1-2 meters, so that foam panels can be conveniently installed on the inner surface of the basement.

To fix the foam with Isospan AM, it is necessary to use a special adhesive composition that does not contain organic solvents. Ceresit CT83 glue has proven itself well.

2.2 Creating a plinth from decorative panels

Installing a false-panel base is much easier than building a brick wall. With the right approach to its arrangement, such a technology for insulating a pile-screw foundation will be durable and reliable.

First of all, you need to take care of the supporting structure to which the plinth panels will be attached. To do this, along the perimeter of the house, it is necessary to weld a guide frame made of a metal profile to the piles.

The step of the guides is determined based on the height to which the house is raised above the ground, as a rule, 2-3 longitudinal profiles are enough. Also, a wooden beam can be used as a frame, but it must first be impregnated with an antiseptic that prevents the wood from rotting.

Insulation plates (extruded polystyrene foam or foam plastic) are attached to the supporting frame. It is necessary to choose the thickness of the plates so that they do not protrude beyond the grillage, since a decorative panel will be attached to it.

Wooden frame for fastening the pick-up

It is important to choose the size of the panel so that its upper part, with which the panel is glued to the grillage, ensures reliable fixation of the structure, and the lower part enters the soil by 4-5 centimeters (you must first dig a small groove).

From the place where the pick-up and insulation are in contact with the soil, it is necessary to remove the soil to a depth of 10 centimeters, and add expanded clay sand.

Expanded clay has low thermal conductivity, and will not allow the structure to freeze in the cold season, as a result of which the heat exchange of the floor and the pile-screw foundation will be minimal.

The technology for arranging an insulated false basement of a pile-screw foundation with Isospan V vapor barrier requires natural ventilation, which is necessary to prevent excessive dampness of the air under the house, the moisture from which will condense on the inner surface of the floor, which can lead to rotting of the wooden structure.

To ensure air circulation, it is necessary to create ventilation holes. On each side of the house, one outlet is enough. In the cold season, the vents are closed with heat-insulating material, or they are shut up with an ordinary rag.

2.3 Technology for arranging an insulated basement on screw piles (video)

Thermal insulation work general information

Membrane film for plinth waterproofing

Membrane film for plinth waterproofing

Work on thermal insulation of the pile foundation of a house or bath should begin after covering the grillage with waterproofing. For the arrangement of waterproofing, special materials are used: membrane-type films, which are shown in the photo above or roofing material. Moisture-resistant material should cover the top of the foundation cushion, on which the walls of the house or bath are located, as well as the side and lower parts of the grillage and the pile heads that adjoin it.

You can study in detail the process of waterproofing the grillage and pile heads of the screw base on the video:

Before proceeding to the construction of a false base with your own hands, you will need to prepare a set of tools. You will need:

- gas welding machine;

- concrete mixer;

- screwdriver, which will be fixed PPS;

- standard construction tools.

An insulated basement can be equipped in two ways: by creating a thin brick wall directly under the pillow of a house or bath, as well as by mounting ready-made decorative panels that are placed on the pillow.

Plinth on the crate

To reduce the cost and speed up the installation of the base, you can make it from sheet materials. Usually, moisture-resistant CBS boards or decorative panels are used for this, corrugated board is also suitable.

The crate is made of metal or wood. Metal elements can be welded to foundation piles. Wooden elements are fastened with bolts in two ways:

- ears for bolts are welded to piles, wooden bars are attached to them;

- vertically arranged bars attached to the grillage serve as the basis for horizontal guides, while there should be a gap between the ground surface and the bars.

To prevent the penetration of moisture from the soil into the sheathing material and the wooden crate, a shallow trench is dug under the future plinth (along the entire perimeter). A layer of sand (2-3 cm) is poured on the bottom and compacted, then a layer of expanded clay is poured. A layer of earth is poured over the expanded clay in such a way that there is no gap between the soil surface and the plinth.

Construction of a false base

Regardless of the option chosen, the first step is to equip the false base.

Types of structures:

Light brick wall.

Pickup from decorative panels.

The first type is difficult to implement. However, this allows you to get a reliable and durable design.

Creating a brick base requires pouring a small concrete foundation

On our site you can find contacts of construction companies that offer. You can directly communicate with representatives by visiting the exhibition of houses "Low-Rise Country".

The procedure for the construction of a brick wall under the strapping:

First, they dig a trench around the entire perimeter of its placement with a depth of 20-25 cm. The width is made with a small margin relative to the size of the brick used. Concrete is laid inside the finished trench: given the slight depth of the foundation, it is additionally reinforced with steel bars 10-12 mm thick.

After the concrete has completely hardened, you can proceed to the brickwork in half a brick. It needs to be built in segments of 1-2 meters: this will create convenient conditions for internal insulation.

As a material for a false brick base, it is recommended to use ceramic brick, which, unlike silicate, copes well with moisture. Tape sheathing is usually used on non-rocky soils.

A panel pickup is set up much faster. On top of the screw piles, steel guides are mounted on bolts or welding. The number of profiles depends on the height of the above-ground part of the piles (usually 2-3 pieces).

A false plinth from panels is created faster, but it is not as reliable

To simplify the further installation of the selected skin, vertical jumpers are attached over the rails. Sheathing is equipped with siding, corrugated board, decorative panels or DSP. Corner sections are decorated with overhead corners and droppers. In order to avoid the destructive effects of ground moisture and frost heaving, the pick-up is made slightly elevated above the ground. The size of the damper gap is in the range of 5-15 cm. During finishing, it can be closed with a decorative strip.

Regardless of which type of false base is used, it must be equipped with ventilation holes that protect the interior from excessive accumulation of moisture. Opposite sides of the structure are the optimal locations for the holes.

Problems of non-insulated pile foundations

For low-rise construction, reinforced concrete piles of a solid section, steel screw and bored concrete piles are most suitable. Regardless of the design of the piles, the method of their installation and the technology of mounting the grillage, this type of foundation has a number of disadvantages.

Disadvantages of a pile foundation:

A pile foundation that is not insulated during the cold season can lead to big problems.

- Cold underground. Increased heat loss through the floor in winter.

- If the grillage is made of reinforced concrete, then a powerful cold accumulator is created. In case of interruptions in heating, it takes a very long time (up to several days) to restore the normal microclimate in such a room.

- Danger of freezing of utilities laid under the floor.

- Pushing piles that have fallen into the freezing zone. Piles are a conductor of cold. If antifreeze measures are not provided, metal and concrete supports can cause local heaving.

- Uneven shrinkage under the weight of the house when individual piles enter zones of low soil density.

- From an aesthetic point of view, a conventional pile foundation is a purely utilitarian design solution that requires decoration.

- The void under the house, blown by the winds, quickly becomes littered and periodically takes time to restore order under home.

Why are individual piles pushed out, leading to a situation where the grillage plane is violated? One of the common reasons is uneven soil moisture: it is stronger around the perimeter and corners than in the center. This, in turn, leads to uneven freezing depth. In addition, the specific expansion during heaving also depends on the percentage of moisture.

4 of the 7 problems listed are directly related to exposure to cold and are solved with the help of a competent thermal insulation device.

Use of Styrofoam

Thermal insulation of foundations implies in most cases the use of such material as extruded polystyrene foam. It differs primarily in its noise and heat insulation properties, which makes it one of the best options for this type of work. The sheet of material is only about 3 centimeters, which saves the internal space that fills the plinth.

When insulating with polystyrene foam, you must follow the following instructions:

- If the wall is made of concrete or brick, it is worth initially eliminating all cracks on it. To better hold the sheets on the foundation, it should be treated with a primer.

- Using special glue, sheets of expanded polystyrene must first be glued on the inside of the basement. In some cases, it is additionally worth fixing them with special umbrellas in the form of dowels. This will help prevent deformation of the sheets of material.

- The joints of expanded polystyrene sheets must also be treated with glue. This will prevent gaps through which cold air can enter in the pile screw foundation.

- If the house is wooden, it is best to carry out two-layer insulation.

- A metal mesh should be glued on top of the sheets. It will help prevent rats and various insects from creating holes in them.

- Under a wooden house, blowing can sometimes occur even in cases where polystyrene foam is used. Therefore, from the inside to the structure, it is worth pouring soil or expanded clay.

Such thermal insulation can make the basement of the house as comfortable as possible in the winter.

Novice home craftsmen often wonder what kind of insulation to choose - mineral wool or polystyrene. The first option has pros and cons. Among the advantages, one should highlight incombustibility, resistance to chemicals, convenience of the material when bending corners, resistance to temperature extremes, high rates of sound and heat insulation.

But this solution also has its downsides. Among others, it should be noted:

- sagging;

- moisture absorption;

- carcinogenicity of formaldehyde resins;

- inconvenience of installation;

- decrease in the effectiveness of thermal insulation over time.

When thinking about the question of which insulation to choose - mineral wool or polystyrene, you must remember that the use of the first solution is possible, but requires care during installation, protection of the material from contact with the room and proper waterproofing. .

Stages of insulation

- Waterproofing grillage and pile racks.

- A frame is being assembled - a structure that replaces the base and serves as the basis for finishing.

- Installation of decorative finishing material on the base.

- Installation of insulation from the inside of the entire structure, elimination of cracks and gaps between sheets.

- Powdering with expanded clay, crushed stone or soil of the basement structure, to strengthen it.

Heat insulator installation

Note! This is an affordable, cheap, but ineffective method. In this way, you will simply achieve partial sealing of the space, there will be no drafts and the floors in the house will become a little warmer, but you can not wait for the desired result.

Therefore, it is better to purchase material that has a low price, but good performance.

- Polyfoam or its analogues just have all these qualities. Thermal insulation is laid from the bottom of the grillage to the first floor of the house. It should be noted that there should be a gap of about a week between waterproofing and thermal insulation work. This is necessary so that the glue or mastic is completely dry.

Facing the plinth with siding.

Facing the plinth with siding.

- The next, last stage, can be considered the final finishing work. After all, the insulation must be protected not only inside, but also outside, and the finish will also have a decorative function. Anyone who is familiar with construction and knows how to insulate the foundation on screw piles will advise you on a lot of materials suitable for this purpose.

The most inexpensive and simple finishing materials can be considered an ordinary profiled sheet. But it is not attractive enough, so if you have the opportunity, you can purchase analogues. Moreover, the range of facade materials offered today is very diverse (See also the article

Imitation plinth

Insulation of facades with foam plastic: we make external thermal insulation with minimal time and money).

It can be decorative brick, stone or their imitation, tiles of various sizes, colors and structures, facade panels. They are often used to insulate the loggia from below, balconies, and other types of external walls.

A special frame is attached to the top of the piles, it will serve as the basis for future finishing. The material of your choice is attached to it.

Imitation plinth

Insulation of facades with foam plastic: we make external thermal insulation with minimal time and money).

Insulation of facades with foam plastic: we make external thermal insulation with minimal time and money).

It can be decorative brick, stone or their imitation, tiles of various sizes, colors and structures, facade panels. They are often used to insulate the loggia from below, balconies, and other types of external walls.

A special frame is attached to the top of the piles, it will serve as the basis for future finishing. The material of your choice is attached to it.

Imitation plinth

Thermal insulation of facades with foam plastic: we make external thermal insulation with minimal time and money time and money).

It can be decorative brick, stone or their imitation, tiles of various sizes, colors and structures, facade panels. They are often used to insulate the loggia from below, balconies, and other types of external walls.

A special frame is attached to the top of the piles, it will serve as the basis for future finishing. The material of your choice is attached to it.

Imitation plinth

Note! For greater comfort in the house, it is not enough to equip its capital bottom. To keep warm, it is also necessary to insulate plastic windows, doorways, and walls that go outside. Only then will you get the maximum result.

Swedish insulated slab: we carry out installation on our own» href=»http://pro-uteplenie.ru/mesta/fundament/114-shvedskaya-uteplennaya-plita»>Swedish insulated slab: osushcheteme.

Basement insulation methods

The easiest option is to blow everything out with penoizol.

Consider how to insulate the screw foundation with each of the presented materials separately, and let's start with foamed glass. As we have already said, it is produced in fairly strong blocks, which you need to work with as with ordinary bricks. Therefore, if you decide to use foam glass, you will need a strip foundation. Foam glass plinth can be finished with your favorite material, it is very versatile.

We will consider ordinary and extruded polystyrene foam together, since the insulation of a house on a pile screw foundation does not differ from these materials. First you need to decide on which side of the crate you will fasten the sheets:

If outside, then the work must be carried out before the finishing DSP boards are fixed. They are subsequently attached through the foam to the crate, the sheets of insulation and trim are in contact. Most often, insulation is carried out in several stages, so you have to fix the foam sheets from the inside. In this case, it is better to do it on the crate, and not between the guides, although the second option is easier to perform. Firstly, a ventilation gap will appear, and secondly, there will be no cold bridges, since wooden beams have a much higher thermal conductivity than polystyrene foam.

The foam is glued to the adhesive foam (it looks like mounting foam), the joints, of course, are sealed with the same foam. Given the fact that there will be only two attachment points for the sheet, additional fixation can be made. Along the guides, on top of the foam, you can fix a thin wooden rail. It is fastened with black self-tapping screws through the foam plastic into the crate. Even on one glue-foam, everything will hold securely, and after fixing with slats, the insulation will definitely not go anywhere.

The easiest way is to blow out the inner surface of the base with liquid penoizol.

After that, he does not need any finishing. Penoizol cannot be used in sheets, as they are very fragile. It should be noted that even if the basement is perfectly insulated, but there is no floor in the house, then you can not count on a positive result. To do this, use mineral wool, it is laid on the crate. The crate is fixed to the base of the house, which rests on screw piles. How to insulate the floor:

- a hydrobarrier is laid on the crate - dense polyethylene is quite suitable, optionally membranes;

- mineral wool is laid on top;

- between the cotton wool and the subfloor lies a membrane that allows steam to pass through.

Pay attention to the fact that steam must exit the heater into the room, and not vice versa. The layer of cotton must be at least 10 cm

If several layers are laid, then this must be done so that the joints do not match. This will eliminate the possibility of cold air entering the house.

Before you insulate the pile screw foundation of your own wooden house, you need to study the technology of work and the necessary materials. The design of the basement in the building performs several functions at once:

- decorative and aesthetic;

- protection of the underground from moisture and wind;

- rise in temperature under the structures of the house.

The last point allows you to get several advantages at once. First of all, this is a decrease in the thickness of the thermal insulation in the ceiling. At the same time, the construction pie becomes larger, the height of the rooms on the first floor is not eaten.

The second positive property of insulation is to reduce the effects of such a phenomenon as frost heaving. Insulation of a pile-screw foundation during wooden construction will help to partially prevent soil movements in winter.

Do I need to insulate

Currently, in the construction industry, much attention is paid to the work on the insulation of walls, basement and other structures of the house. This is due to the fact that energy resources are limited, and their cost is quite high. To increase the energy efficiency of a building, it is necessary to carefully consider the insulation.

Options for warming the basement of a house on a pile foundation

Heating costs can be up to 40% of the family budget. And these costs are permanent. Knowing the cost of utility bills and the amount of work on insulation, you can easily calculate when the measures taken will pay off.

It is also important to remember that a well-insulated structure is protected from condensation. Humidity is the main cause of mold and mildew. You can also easily encounter other microorganisms. Insulation of the pile foundation will help preserve the health of the inhabitants of the house, as well as reduce the frequency of repairs and replacements of the flooring on the ground floor.

Insulation options

Facing the basement can be of several types. The decision which one to use is made on the basis of aesthetic considerations, financial possibilities, as well as the qualifications of the workers who will perform the finishing.

Basement insulation can be carried out in two ways:

- on a separate tape design;

- along the crate, which is attached to the piles.

Tape construction

The first option is more difficult and also has a number of limitations. Shallow type tape construction can be made of concrete or brick. Most often, it rests on the ground or its small monolithic foundation (more on the device). But when building on heaving soils, it is strongly not recommended to use this option. Especially when it comes to brick plinth. In this case, the earth rises (swells) in winter. Moreover, the process is uneven. Having dug out the structure of the plinth from the snow, at some point you will have to see inclined cracks that indicate damage by frost heaving.

This phenomenon can be prevented by eliminating one of the heaving factors:

- low temperature;

- moisture.

It is impossible to fulfill the first condition in the manufacture of an unburied tape. The soil under the basement sheathing of the house will still freeze and deform. Moisture removal may also be inefficient.

It is reasonable to use tape sheathing only on those soils that are not prone to heaving. Such bases include coarse-grained soils, medium or coarse sand. Also, the option is suitable for regions with a warm climate, where negative temperatures are rare.